SR600 series

Features

Product Details

SR600 series polymer positive temperature coefficient thermistor

● Low voltage circuit overcurrent protection

● Working current: 0.03A-0.2A

● Impulse voltage: 600V

● Comply with RoHS certification, halogen-free encapsulation material

● Agency approval: UL (E312438)

★ Electrical performance (25℃±2℃)

|

Product model

|

IH

|

IT

|

IMax

|

VMax

|

Trip

|

Pdtyp

|

RMin

|

RMax

|

R1Max

|

|

|

(A)

|

(A)

|

(A)

|

(V)

|

(A)

|

(S)

|

(W)

|

(Ω)

|

(Ω)

|

(Ω)

|

|

|

SR600-030

|

0.03

|

0.06

|

3.0

|

400

|

0.5

|

5.0

|

1.0

|

70

|

120

|

200

|

|

SR600-050

|

0.05

|

0.10

|

3.0

|

400

|

0.5

|

5.0

|

1.0

|

50

|

90

|

350

|

|

SR600-110

|

0.11

|

0.22

|

3.0

|

400

|

0.55

|

5.0

|

1.5

|

10

|

19

|

30

|

|

SR600-150

|

0.15

|

0.30

|

3.0

|

400

|

0.75

|

5.0

|

1.5

|

6.0

|

12.0

|

18.0

|

|

SR600-160

|

0.16

|

0.32

|

3.0

|

400

|

0.80

|

5.0

|

1.5

|

4.0

|

10.0

|

15.0

|

|

SR600-200

|

0.20

|

0.40

|

3.0

|

400

|

1.0

|

10

|

1.5

|

5.0

|

9.0

|

14.0

|

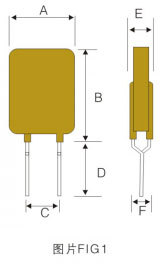

★ Size(mm)

|

Product model

|

A

|

B

|

C

|

D

|

E

|

F

|

Lead

|

FIG

|

TUV

|

|

max

|

max

|

typ

|

min

|

max

|

typ

|

Φ

|

|||

|

SR600-030

|

7.0

|

11.5

|

5.1

|

7.6

|

6.0

|

/

|

0.60

|

1

|

|

|

SR600-050

|

7.0

|

11.5

|

5.1

|

7.6

|

6.0

|

/

|

0.60

|

1

|

|

|

SR600-110

|

7.0

|

11.5

|

5.1

|

7.6

|

6.0

|

/

|

0.60

|

1

|

|

|

SR600-150

|

14.5

|

12.6

|

5.1

|

7.6

|

6.0

|

/

|

0.80

|

1

|

|

|

SR600-160

|

14.5

|

12.6

|

5.1

|

7.6

|

6.0

|

/

|

0.80

|

1

|

|

|

SR600-200

|

19.5

|

9.5

|

5.1

|

7.6

|

6.0

|

/

|

0.80

|

1

|

|

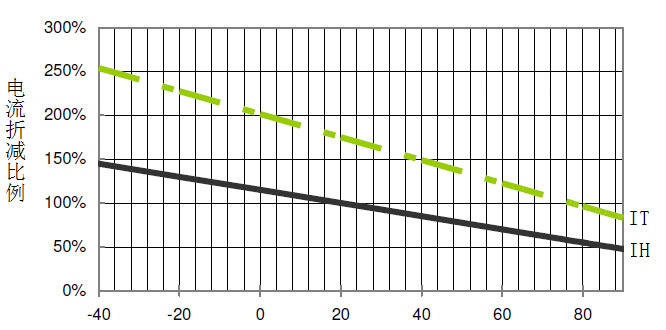

★ The IH and IT current reduction rate of PPTC at different ambient temperatures

|

Temperature

|

-40℃

|

-20℃

|

0℃

|

23℃

|

40℃

|

50℃

|

60℃

|

70℃

|

85℃

|

|

Percentage reduction

|

145%

|

130%

|

120%

|

100%

|

88%

|

80%

|

71%

|

66%

|

56%

|

★ IH and IT current reduction diagram of PPTC at different ambient temperatures

★ Physical properties

Lead material: SR030-SR200 tinned copper clad steel wire

Insulation material: Epoxy resin polymer meets UL94-V-0 requirements

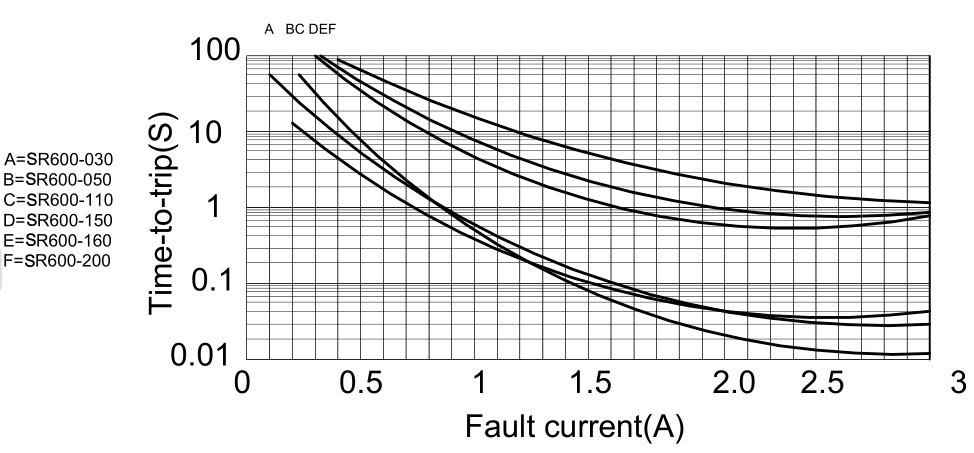

★ PPTC operation protection time curve table at 25℃±2℃

★ Conditions of use

1.The working ambient temperature is -40℃~85℃.

2.Exceeding the applicable conditions of this product or other inappropriate use may cause damage, and may even cause electric breakdown or flames.

3.PPTC components are designed for occasional overcurrent in circuits, and are not recommended for use in circuits with continuous and continuous overcurrent.

4.Avoid contact with chemical solvents for PPTC components. Prolonged contact will damage the performance of the components.